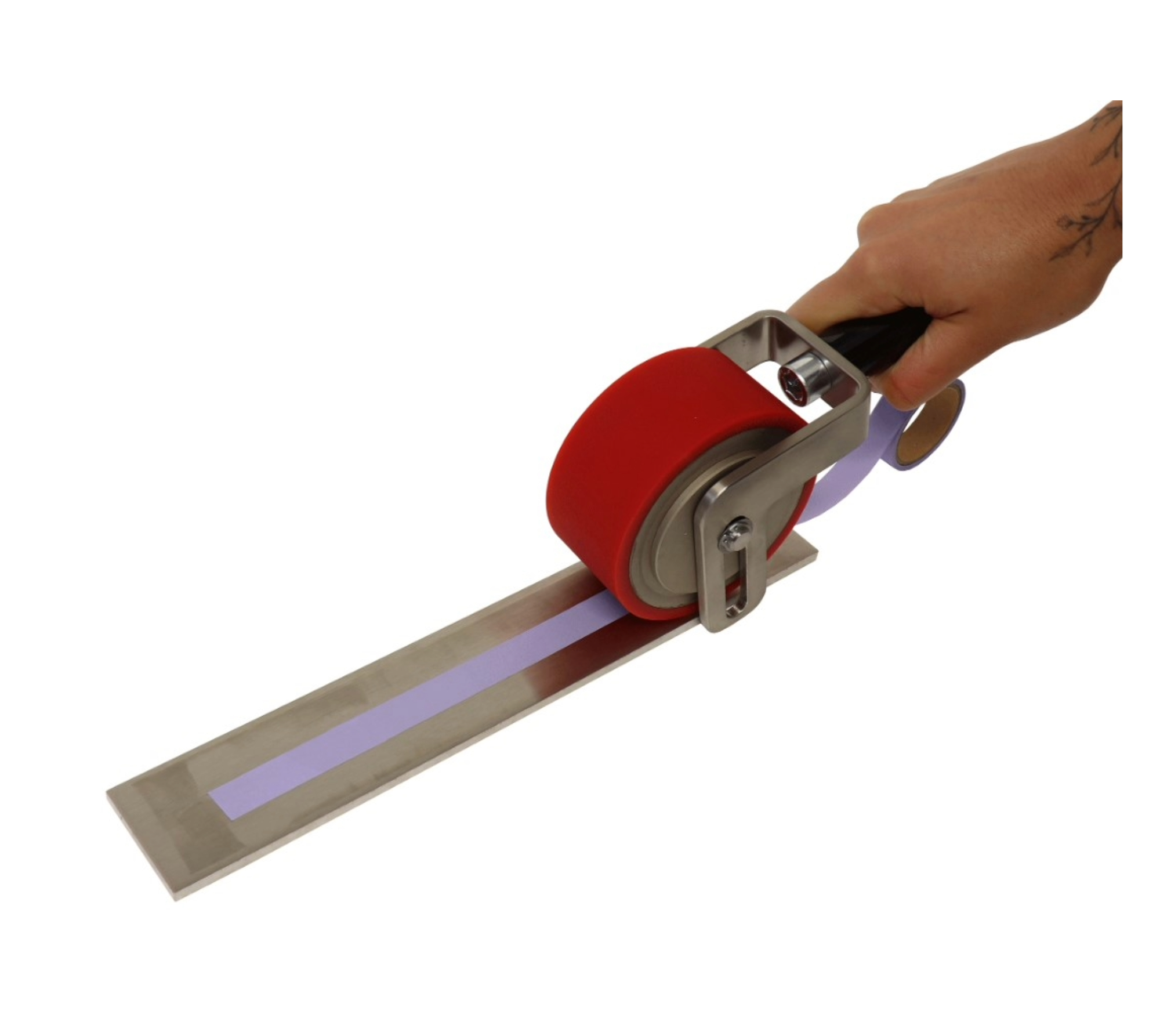

Peel roller is used to apply adhesive sample to a test panel of the peel fixture with an even pressure.

According to ASTM-D3330, DIN EN1939, DIN EN ISO29862.

Why Use a Peel Roller?

- Ensures the adhesive is applied with uniform pressure across the sample length and width.

- Standardizes sample preparation, which is crucial for reliable comparison between tests.

- Eliminate trapped air between adhesive layers and substrates, which could otherwise affect bond strength and lead to premature failure.

- Uniform pressure promotes optimal contact between adhesive and substrate, allowing for better bonding performance.

- Many test standards require or recommend using a standardized peel roller for sample prep. For example, ASTM D3330 for pressure-sensitive adhesives.

- Reduces human error, especially in cases where subjective or inconsistent hand pressure would otherwise affect results.

Specifications

- Rubber hardness: 80+/-5 Shore A

- Rubber thickness: 6+/-0.5 mm

- Roller width: 45 mm

- Roller diameter: 95 mm

- Weight: (only roller without handle): 2040 g +/-45 g

- Roller (non-rubber parts): Steel, nickel-plated + Polyurethane coated

- Handle: Stainless steel V2A + plastic

- Temperature range: 0 … +70°C

Included Items

- 1 peel roller